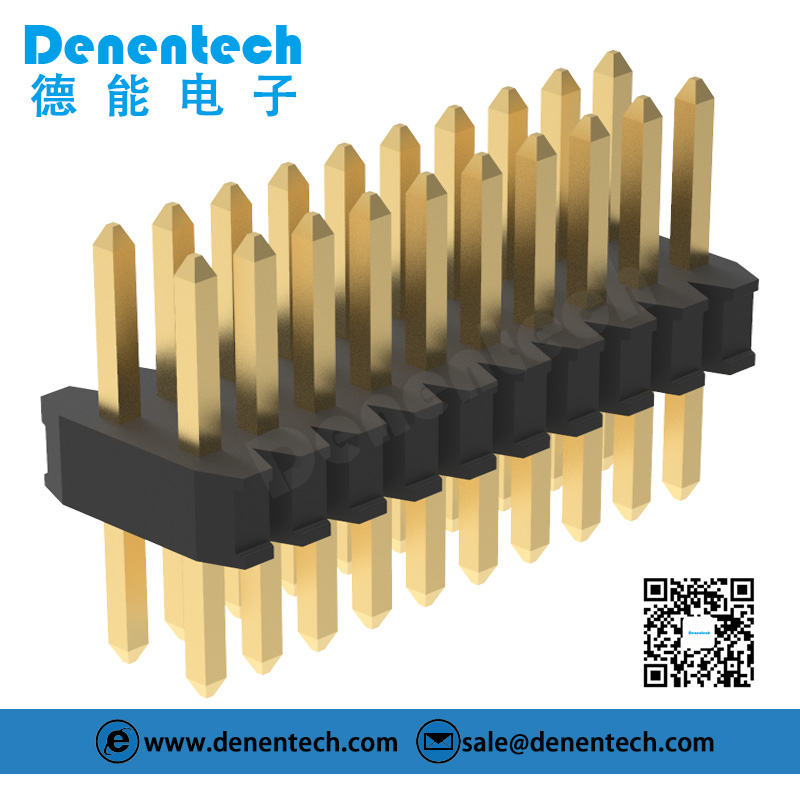

In electronic components, product design is often related to the performance of the product, good design can not only improve the beauty of the product, but also prolong the service life of the product, today we can talk about the knowledge of the needle in the connector. According to the number of rows, the pins can be divided into single row, double row, three row, and four row. Currently, the upper limit is four rows.

Connector development should be miniaturized (because a lot of products face smaller and lighter development, for spacing and appearance size, height has certain requirements, this product requirements will be more precise, such as a good choice of line to board small spacing 0.6mm and 0.8mm), high density, high-speed transmission, high frequency direction development. Miniaturization refers to the smaller spacing between the center of the PIN row, which is often referred to as the PIN distance in the industry. High density is to realize the number of large cores.

The function of the row pin is to connect the circuit and take up the task of current or signal transmission. Usually used in conjunction with the row of pins, forming a board-to-board connection; Or with electronic wiring harness terminal matching use, form a board-to-wire connection; It can also be used independently for board to board connection. We take a risk in avoiding the electronics designer underestimating the importance of a single row of needles in the design process. This is the idea that design must be bipolar; There is a need for strong design, etc.

Single row of needle design advanced single row of needle in the manufacture of raw materials white bright, needle row mother which good, color between silver and nickel, the initial weldability is still acceptable, high temperature aging or long-term storage weldability reduction is more serious. The gold-plated underlayer originally used for decoration in contact with the human body can also be used in white tones with higher electrical performance requirements, but it has higher resistance to change and meets certain weldability requirements.

Having said that, how on earth should we choose the row of needles? When people choose needles, cost control is the first consideration. Others are high quality, high stability, and design features of the needle itself. To put it bluntly, choices are not only rugged and inexpensive, they are for their own use. So substitute manufacturers have become a good choice. Not only quality in place, price is also a big advantage. The bigger advantage lies in the delivery time.