Connectors are one of the important components in electronic products. They are important interfaces that connect various electronic devices such as circuit boards, power supplies, and electrical appliances to each other.

The process flow of connector production can basically be divided into the following four stages:

1. Stamping: The manufacturing process of electronic connectors generally starts with stamping pins. Electronic connectors (pins) are stamped from thin metal strips using large high-speed stamping machines. One end of the large roll of metal strip is fed into the front end of the stamping machine, and the other end passes through the hydraulic workbench of the stamping machine and is wound into the take-up wheel. The metal strip is pulled out by the take-up wheel and rolled up to stamp out the finished product.

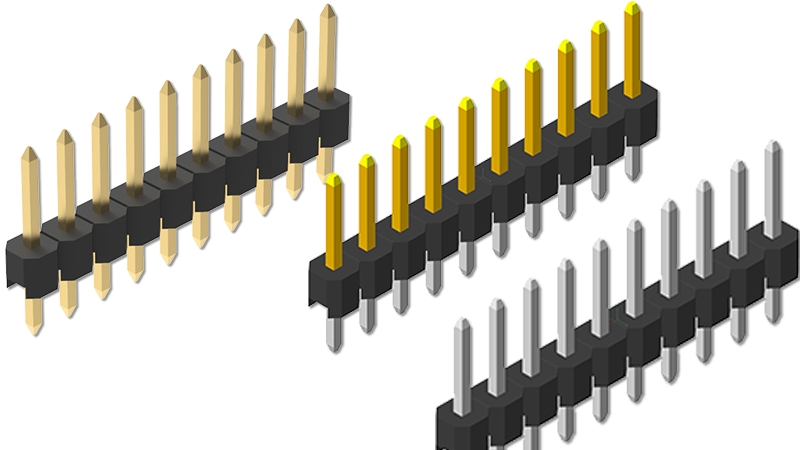

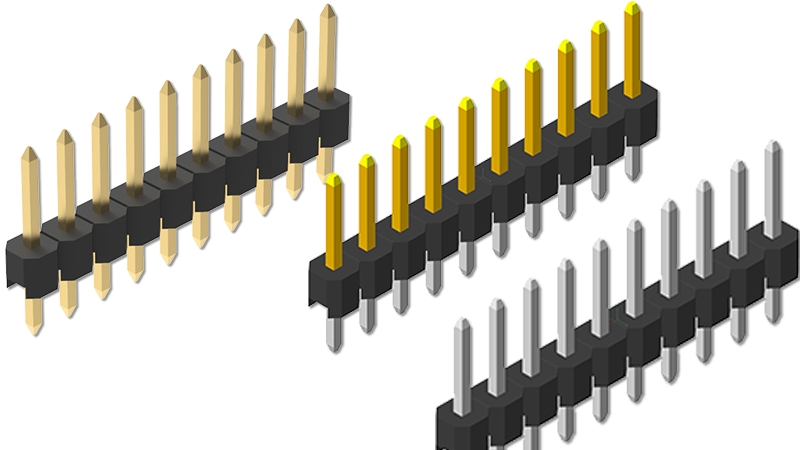

2. Plating: After the connector pins are stamped, they should be sent to the plating section. At this stage, the connector's electrical contact surfaces are coated with various metal coatings. Problems similar to those in the stamping stage, such as twisting, cracking or deformation of pins, will also occur when the stamped pins are fed into the plating equipment.

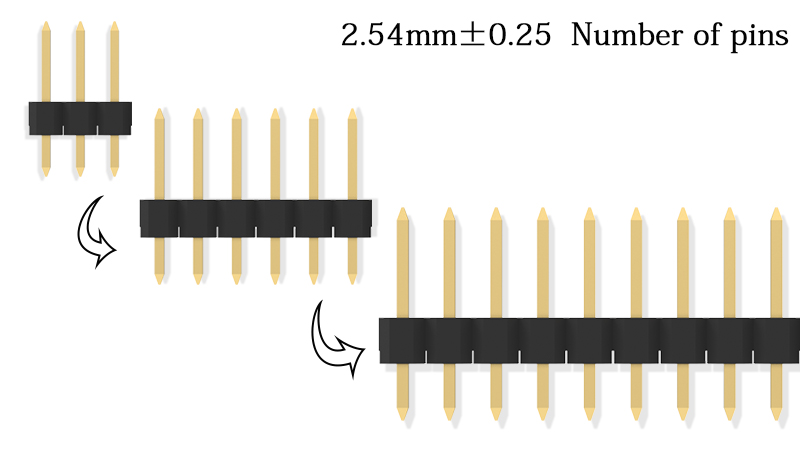

3. Injection molding: The plastic box holder of the electronic connector is made in the injection molding stage. The usual process is to inject molten plastic into the metal membrane and then quickly cool it into shape. So-called "leakage" occurs when the molten plastic does not completely fill the membrane. This is a typical defect that needs to be detected during the injection molding stage. Other defects include filled or partially blocked connector holes (these connector holes must be kept clear and clear to allow for proper insertion of the pins during final assembly). Since leaks in the box base and blocked connector holes can be easily identified using backlight, the machine vision system used for quality inspection after injection molding is relatively simple and easy.

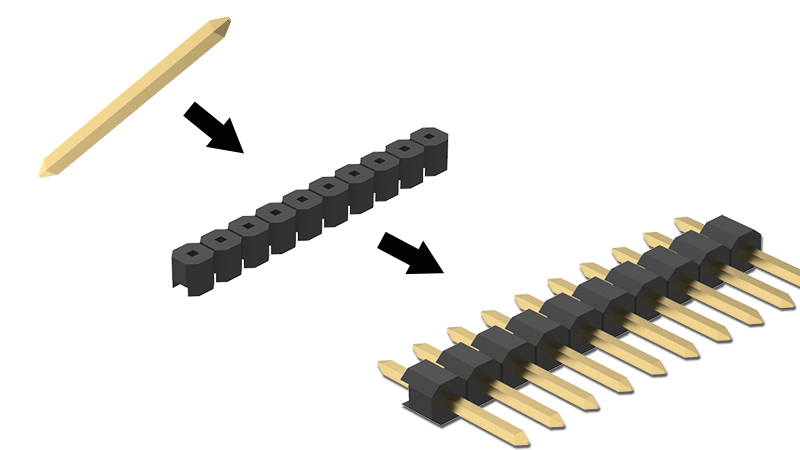

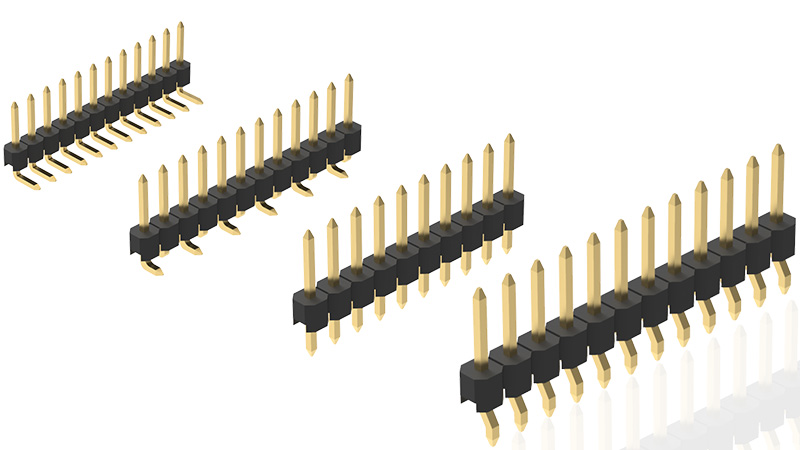

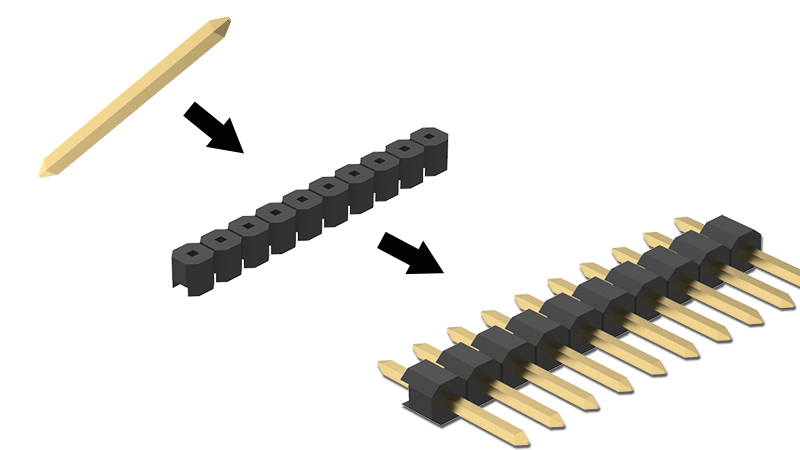

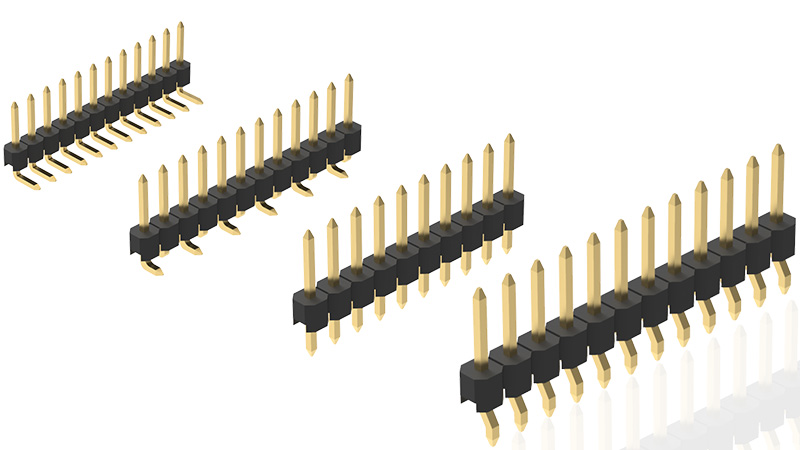

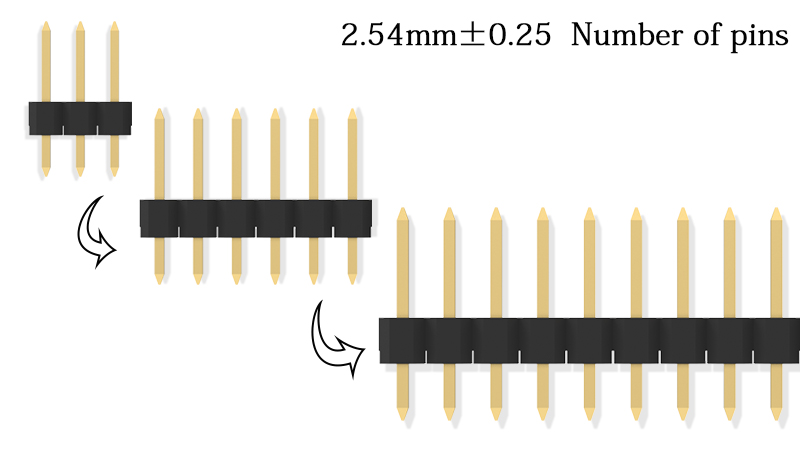

4. Assembly: The final stage of electronic connector manufacturing is the assembly of finished products. There are two ways to connect the electroplated pins to the injection molded box base: separate plugging or combined plugging. Individual plugging means connecting one pin at a time; combined plugging means connecting multiple pins to the box holder at the same time.

Denentech connector manufacturer, with 300+ specifications, source manufacturer, one-stop supply chain, high production capacity, high quality and stable delivery. It has more than 1,000 cooperative customers, has been certified by the state, and complies with national certification standards.